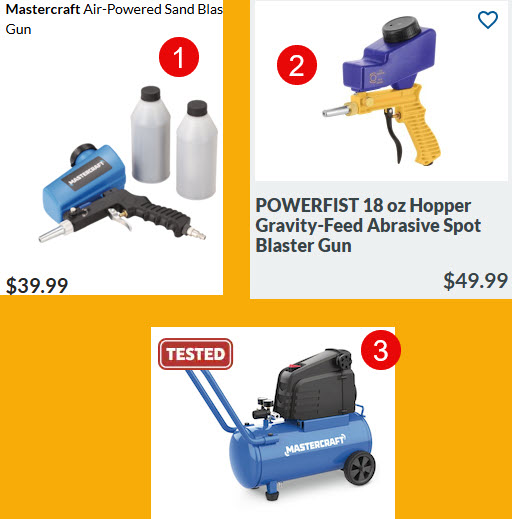

Wanted to get the engine’s top end cleaned up before putting the whole puzzle back together again. The Barrel will be getting a fresh coat of VHT high-temp paint—because nothing says “I tried” like paint that can actually survive a warm day.

I did consider cleaning everything myself, but with all those fins on the Barrel and the Head, it was like trying to scrub between a porcupine’s toes. As you saw in my last post, there was enough dirt packed between the fins to start its own postcode, plus 55-year-old paint hanging on for dear life. Without sand blasting or vapour blasting, the whole job looked about as appealing as hand-polishing a hedgehog—so aye, not happening.

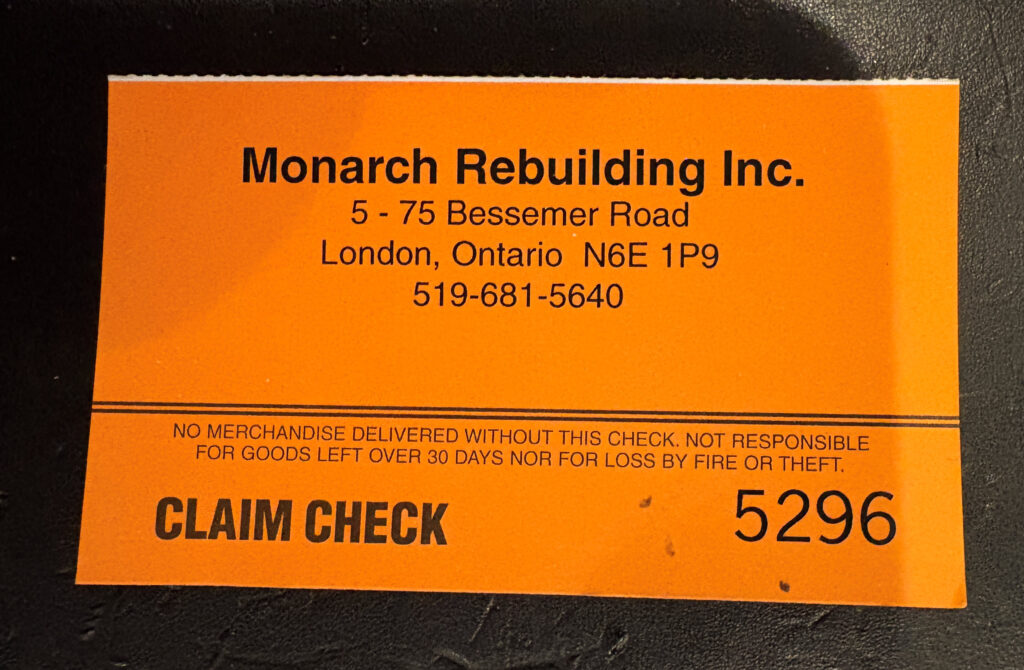

John Johnson from the CVMG pointed me toward a company called Monarch Rebuilding, so I gave them a shout. They kindly offered me the “friend of John” pricing—which, knowing my luck, probably means a wee extra added on for the privilege.

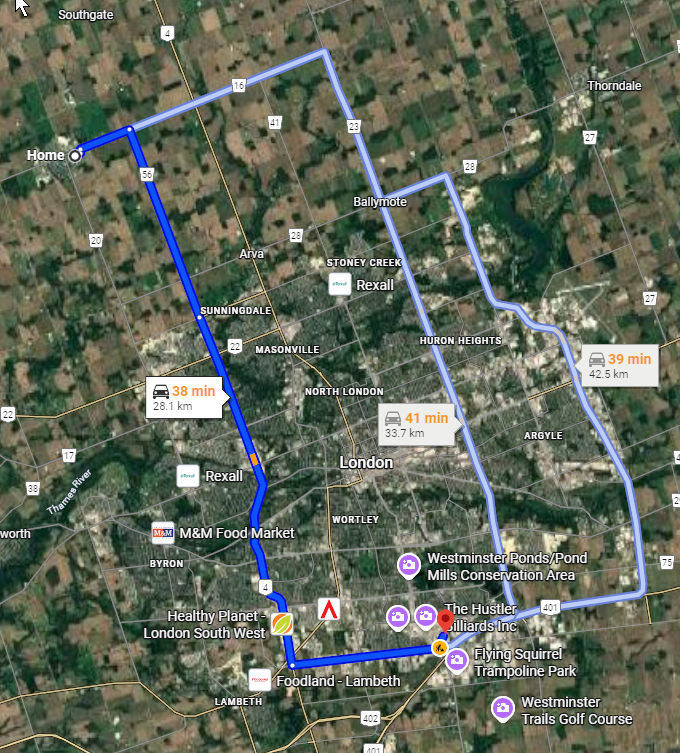

My other option was the old DIY route, and I even looked at a couple of the “recommended” hand-held blasters from Crappy Tire and Princess Auto. Aye, proper high-end equipment… if you’re restoring a toaster. My garage compressor is only an 8-gallon wee beastie, puffing away like a pensioner on a hill climb, so it’s well below spec for any serious blasting.

Sure, with enough stopping and starting I might manage it, but that sounds like the sort of trial best left for spring—when the weather’s warm enough that my fingers don’t freeze to the tools. I could try to reclaim the blasting media to save a few quid, but out in the winter or late-fall cold? Aye right. That’s just adding another layer of misery to the job.

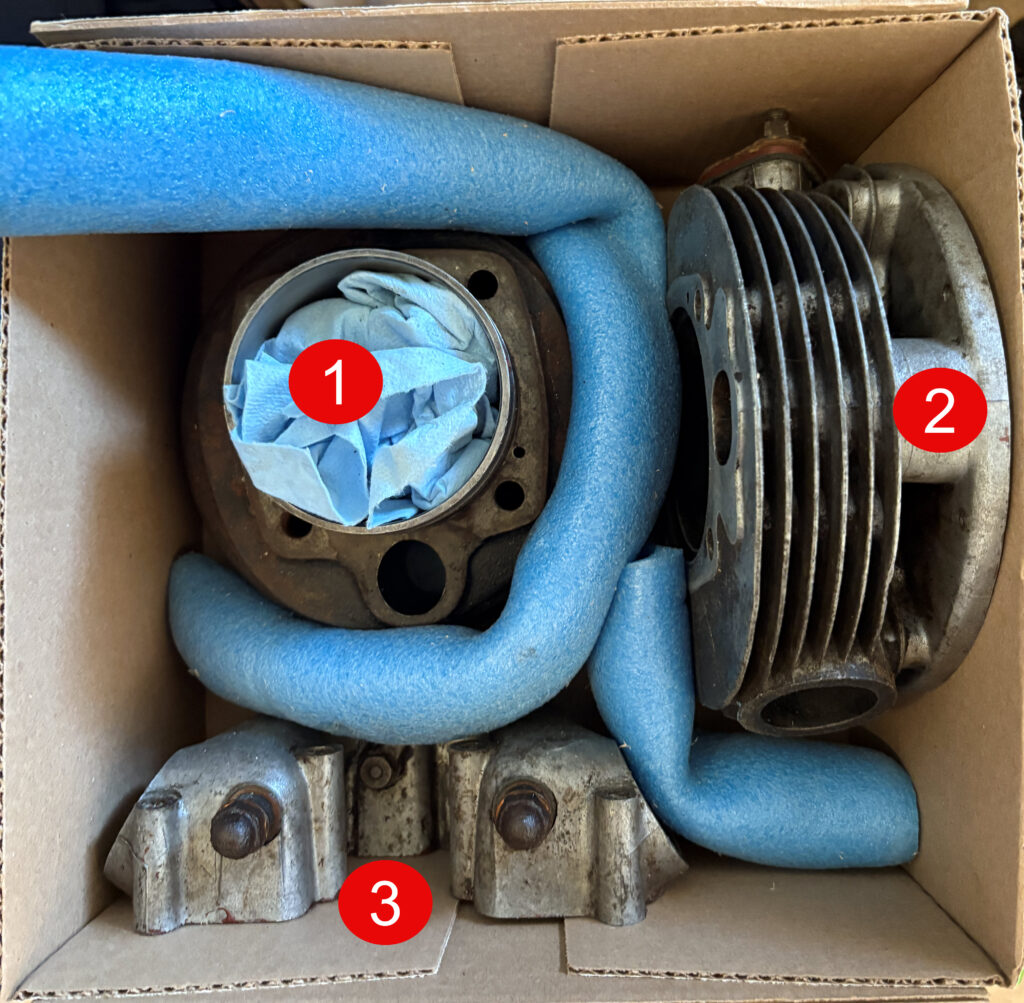

So I packed the parts up today, stuffed a bit of pool noodle in there for padding—very high-tech, NASA-approved packaging—and sent Holly off to St. Thomas with the box. She dropped it off on her way back from her program, probably wondering why she’s now part of a BSA logistics operation

Apparently it’ll be ready for pickup Monday or Tuesday, so once it’s back in my hands I’ll post the next thrilling chapter. Fingers crossed no surfaces are damaged—because after all the emails, assurances, and “oh aye, we know exactly what we’re doing,” I’m expecting nothing short of perfection. Full confidence… or at least enough to pretend I’m not sweating over it.

Let the dice roll. The box is away, the die is cast, and my stress level is now officially in the red.

hope they plug off any oilways or threaded holes or your going be spending a long time cleaning the grit out .

all threaded holes should be covered too I used removeable silicone , the VHT works better if you can heat it in the Oven when the wife isnt home .

I have a friend with an ultrasonic cleaner, but they told me they would. Went with trust to start as I have a plan to clean further.

I like the VHT tip and I will plan that. What temp for how long.

I believe the temperature is marked on the VHT can I did my barrels with the wrinkle finish and the heat made a big difference to bring out the wrinkles