Bit of Back-story: Over Christmas, I treated myself to a pair of Rupert’s books — one for the engine, and one for everything but the engine. (Because why make things easy and put it all in one?) They’ve been brilliant references for my B40 project, and I’ve even exchanged a few emails with the man’s team. A fine chap named Dave Smith replied with extra details — clearly the poor soul assigned to deal with daft questions from folks like me.

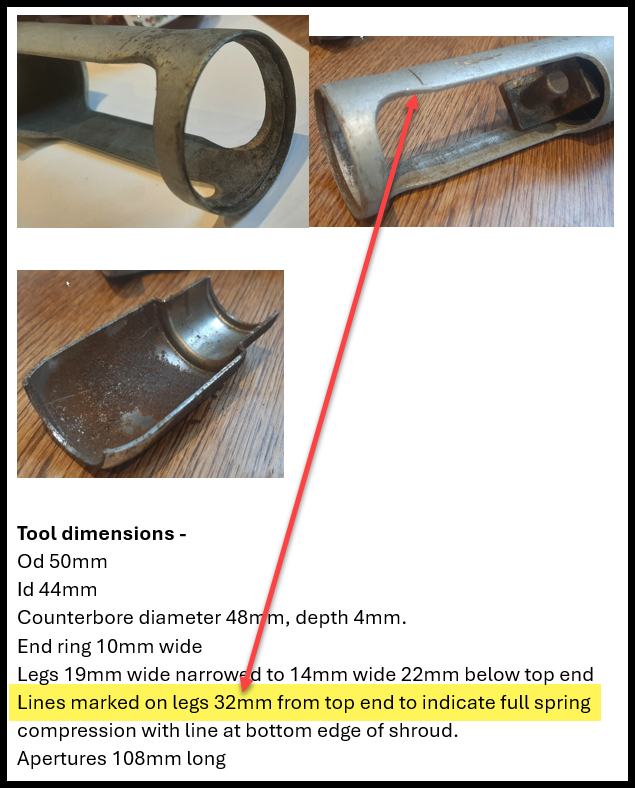

I’d reached out for more info on the tool used for dismantling the rear shocks — specifically, the one meant to remove the chrome collets. Mine, naturally, wasn’t working. (Because why would it?) I just wanted to confirm a few basic dimensions, but Dave went above and beyond — sent photos, measurements, and probably wondered how someone could overthink a spring compressor quite this much.

The magic number, as it turns out, was 32 mm — that’s the proper compression point for the spring, or so the gospel according to Rupert says. I can’t say for certain, but I reckon I convinced myself it was fully compressed somewhere around 24 to 25 mm — optimism is a powerful tool, after all.

Thursday afternoon found me over at Mario’s, where the two of us gave it a proper go. With a bit more persuasion (and a few creative words), we edged closer to the 32 mm mark I’d scratched on my tool. Somewhere between 30 and 32 mm, one of the chrome collets finally surrendered — followed shortly after by the second, with just one more encouraging turn.

As for that minor counterbore some folks swear by — I’m fairly certain it serves no real purpose except to waste a bit of time and metal. I skipped it entirely, and my tool worked just fine, thank you very much.

The shock assembly (in all its glorious pieces) is shown to the left, and I can finally get on with cleaning it up. I gave the hydraulic portion a few test strokes — purely scientific, of course — and it seems to be working fine, no oil leaks in sight. The seals aren’t replaceable, but let’s be honest, at this age I’m barely replaceable either.

Now comes the great debate: do I settle for a good cleanup and maybe a bit of nickel plating to make them look respectable again, or do I fork out roughly $175 for a shiny new pair? My wallet says “polish it,” but my pride says “treat yourself.” We’ll see which one wins — odds are, it’ll be the cheaper voice in my head.

And on that triumphant note — naturally, the universe had to balance things out. My trusty compression tool decided to retire early, failing spectacularly while I tried to tackle the next shock. Aye, nothing says “progress” quite like ending the day with a pile of parts and a broken tool.

So, it’s back to the drawing board (and the grinder) to rebuild the compression assembly — stronger, smarter, and hopefully daft-proof this time. Until then, the last shock will just have to sit there looking smug.

Stay tuned — because if history’s any guide, the next update will feature either triumph or more swearing… possibly both.

Good luck with that sounds like a pain in the ass . Buy the parts 😂

My mechanic BSA SME is my money saving voice and he reminds me there are lots of expenditures coming, so I must be conservative at each step for the first version of the rebuild. I have wheels+spokes, seat, gas-tank, chain guard to come, so can’t loose sight too soon. That said it might turn out to be the best forward unless you can find some for me in Scotland and ship them bro :o)