Not bad for $10 in scrap steel with some left over.

This is what it looks like so far. My neighbor did the welding and it’s tricky to do the tack welds and then how to keep everything square and aligned as you fill the welds (heat warping the steel). The part on the left we made so it fits together with a joint so that it can be removed. It’s only required if you tip the assembly down to work on either side of the motor.

I spoke to one of the CVMG guys (mechanic) and he said back in the day they just put them in a wooden box (remove sides likely) as an engine holder. Of course not so easy to find a wooden box anymore as that was likely when vegetables came in them :o)

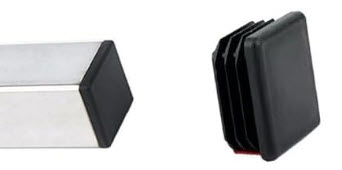

Next steps are to get some black rattle can paint and put a few coats on it with maybe a coat or two of clear coat… then I will put in the plastic plugs for the ends that I got from amazon,

I still have to measure and drill the holes to mount the engine before I do the pretty work and before it starts rusting…..

Right on, you’ll be lifting the engine out in no time. Great work, good neighbour what a team.