I had a wee bit of choice when it came to the frame. Earlier on, I’d broken it down into its three main bits — the front loop, rear section, and swing arm. One tempting option was to have it sandblasted and powder coated. I even got a quote for about $300. Not bad, but that’s a fair few pints of Guinness or a new set of gaskets, depending on your priorities. DIY saves money.

A few of my CVMG pals, always eager to offer “advice” (especially when it’s not their back doing the sanding), suggested I save the cash and just rattle-can it myself. “It’s mostly hidden when the bike’s together anyway,” they said — aye, the same logic used when choosing socks for a kilt.

And they’ve got a point — once the tank, engine, and wheels are back on, the frame’s about as visible as a haggis in the Highlands. But powder coat has its downside too: once it chips, you can’t just touch it up without it looking like a bad paint job on a pub wall.

At one of our CVMG meetings, I had a good blether with Bruce. He told me about his garage setup — and I swear it sounded like the Rolls-Royce of sheds. He’d just installed a two-stage compressor that could probably power a small jet, never mind a sandblaster.

Bruce’s done his own painting before and was generous with the tips — the man’s clearly sprayed more things than a Scottish midge in summer. Better yet, he offered to let me use his setup to sandblast my frame. After a bit of calendar juggling, I made the trip out to Thorndale last week, where I also picked up some primer he recommended from a local shop.

So now the plan’s set — the frame’s getting the DIY treatment. Let’s hope by the end it looks more “classic restoration” than “crime scene cleanup.”

Blasting Away – The Frame Gets a Proper Scrub

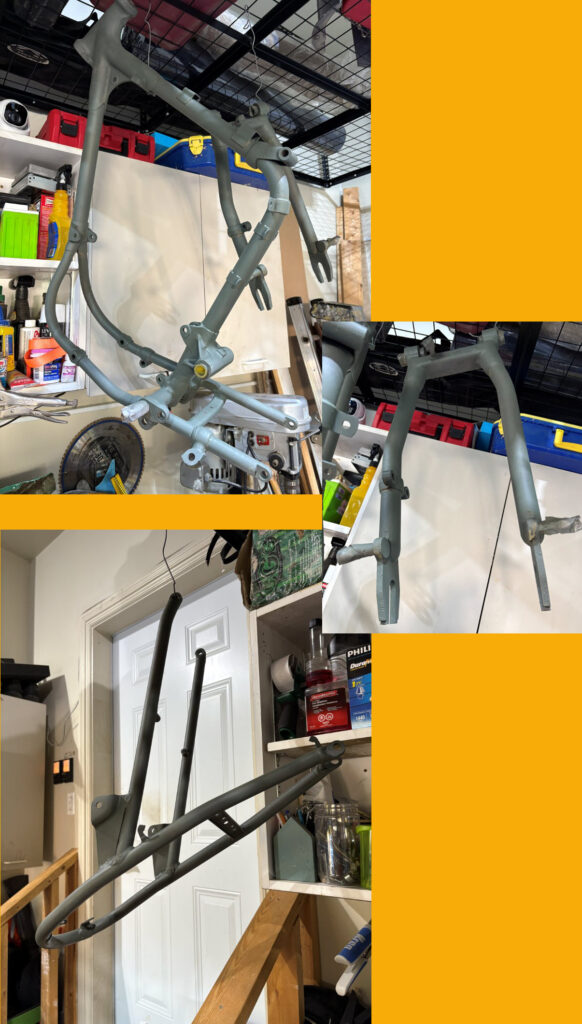

Below you can see the finished pieces — or as I like to call them, the “shiny survivors.” I went through a full 50-pound bag of glass bead and even dipped into a wee bit of Bruce’s stash to top up the hopper. (Aye, he caught me red-handed, but I told him it was for the good of British engineering.)

You can spot the setup in the lower right of the photo — a proper DIY sandblasting station on the trusty Workmate bench. By the time I was done, the top of that poor bench was cleaner than a freshly shaved Scotsman on wedding day.

The results were brilliant — the paint practically lept off the frame, and the brazing welds came through like gold veins in a miner’s dream. I’d plugged all the important holes and taped the threaded bits with duct tape (as any true craftsman would).

By the end of the day, I was covered head to toe in dust, deaf from the compressor, and grinning like a loon. But aye — this day was a grand success! Glass kept raining from my hair each time I scratched an itch.

Paint Like Ye Mean It

Next up, I cobbled together a state-of-the-art paint booth — right outside the garage, tucked neatly in the corner by the fence. A hockey stick served as my parts hanger (because this is Canada, after all), and I nailed a cardboard box to the fence to catch overspray. The neighbors must’ve thought I was either painting a masterpiece or opening a back-alley repair shop.

To my surprise — or perhaps against all odds — it actually worked a treat! With just one rattle can, I managed two coats, and they turned out rather decent (In My Own Humble Opinion, which of course is the only one that matters – next to E’s).

Now I’m convinced I can build a proper version of this “booth,” maybe even with walls that aren’t flapping in the wind. I’ll be spraying the frame in black next, with a few layers of clear to make it shine like a freshly polished sporran.

Aye, the future’s bright — brighter than the paint, even.

The Battle of the Bearing Races

Before I can get too carried away with paint and glory, there’s still the small matter of those blasted bearing races hiding up in the goose neck. They’re seated in there tighter than a miser’s wallet on payday. The inside diameter of the neck is smaller than the races themselves, so there’s no handy lip or edge to catch with a drift or puller — just smooth steel mocking me.

The plan? I’m teaming up with my neighbor to try the “welder trick” — a fine bit of mechanical sorcery where you run a bead around the inside of the race so it contracts and practically falls out. Or so the legends say. A couple of the CVMG lads swear by it, though they also said Triumphs don’t leak oil, so I’m taking it with a pinch of salt.

If all goes well, the races will drop out nicely, and if not, well… there might be some colorful language echoing down the street. Either way, it’s the next step before paint — and with a wee bit of luck (and maybe a fire extinguisher nearby), we’ll get it done.

How To: Remove bearings with a welder

Aye, the primer’s on — and while it didn’t look like it covered perfectly in the photos, trust me, it’s consistent. (That’s my story, and I’m sticking to it.) The finish feels smooth, no bare patches, and everything’s sealed up nicely for the next stage.

I’m actually quite chuffed with how it turned out. The rattle can behaved itself for once, and I managed not to coat half the fence in green mist. Now I’m just waiting for a stretch of good weather to hit it with the black.

The plan calls for low humidity — which, judging by the last few weeks, shouldn’t be too hard to come by — and little to no wind. Nothing ruins a paint job like Mother Nature deciding it’s time for a dust storm. With a bit of luck, and maybe a calm day or two, I’ll finally get that lovely black finish on and follow up with a few coats of clear for good measure.

A Wee Bit of Sandblasting… Sort Of

I like to call it “sandblasting,” though technically I was using glass beads — but let’s not split hairs, eh? Same satisfying racket either way.

Next on the list are some nuts and bolts on the sheet metal that need to come off. A few will get the polite treatment, and the rest… well, that’s what grinders and nut splitters are for. Once the hardware is out of the way, it will be time for the wire wheel — a proper bit of elbow grease to get everything ready for paint. Nothing like a bit of steel-on-steel action to make a man feel alive.