Hope it’s clear now how the engine stand works. The extended leg lets me lay the motor down on either side, which is handy for maintenance, or for when I just want it to think about what it’s done for the past 64 years. The top end is fully accessible, which is both exciting and mildly terrifying.

I still need to go get proper bolts and washers, but for now I’m using the frame bolts just to hold it in place. You know, the old “don’t worry, it’s temporary” approach — the same philosophy that keeps duct tape sales strong.

In the last photo, you’ll see the stand was not yet painted, but I did manage to install some Amazon.ca plastic plugs. Because nothing screams “professional restoration” like $4 worth of imported plastic caps.

The Removal Process (or: How to Test Your Friendships)

- Exhaust valve release cable: Removed from the top end. No drama here, which immediately made me suspicious.

- Oil feed lines: These deliver oil to the top valves and gravity drains it to the sump. I put hoses over the feed points with the nuts attached to keep out dirt. This was mostly successful, except for the bit where I got oil on my shirt anyway.

- Distributor wire: Disconnected, which means the bike can no longer spark — or judge me silently from the corner.

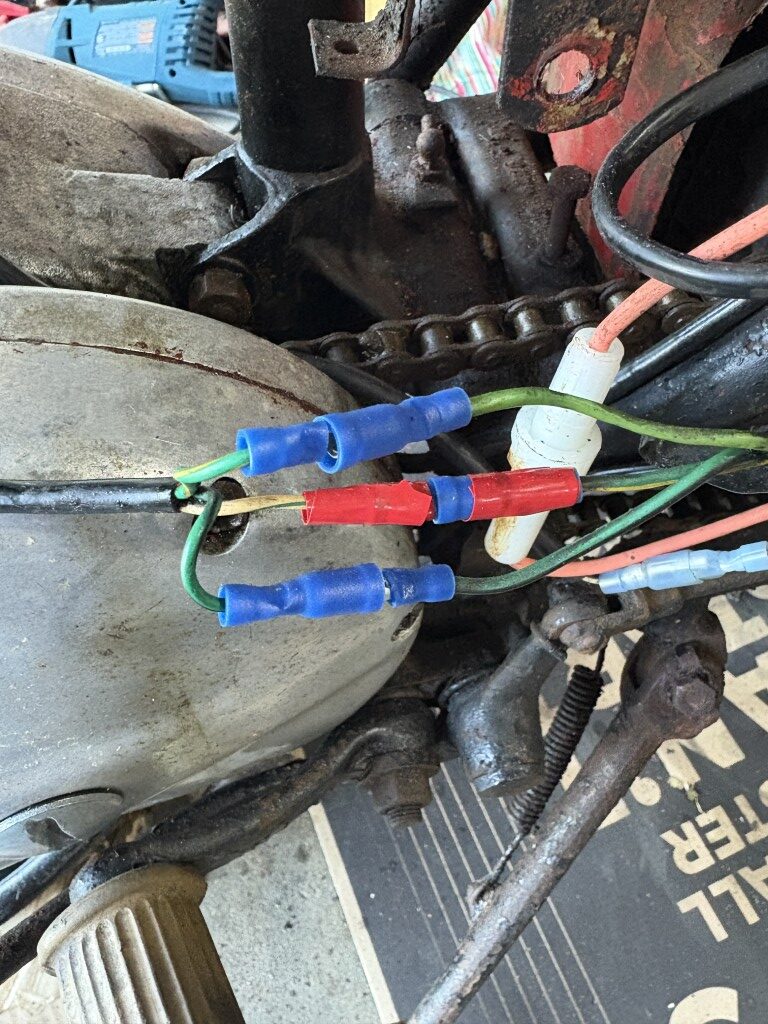

- Generator wires (3): Removed. These are responsible for charging the 6V battery and coil. I labeled them carefully to avoid future “why won’t it run?” meltdowns.

- Clutch cable: Still attached inside the right side, so I disconnected it at the lever and wrapped it around the top. Very professional. Definitely not what you’d call “farm-engineered.”

- Carburetor: Removed and covered with a precision-machined dust shield (aka a scrap of cardboard). NASA, eat your heart out.

- Kickstart lever & gear shift: Already removed earlier during the “exhaust pipe fiasco,” which you may recall was resolved with a Sawz-All.

- Engine mounts: Three bolts: front, rear (stud with two nuts), and cross bolt underneath. Each one removed without incident — which makes me think the engine knew what was coming and decided not to fight.

Extraction Team: Me + Neighbor

This was a two-man lift. We raised the front, lowered the rear, twisted the motor clockwise, tilted it right, rotated it 90 degrees, and finally set it down on cardboard. If it sounds like a complicated dance move, that’s because it was. I’m pretty sure we invented the “BSA Salsa.”

With the engine out, I wrestled it into the stand and bolted it in. Front bolt first, then rear. It now sits like some ancient relic on display — equal parts intimidating and oddly majestic.

The Plan

One of my friends from the CVMG London branch, Mario (because every restoration needs a Mario), has generously agreed to help me break the engine down and rebuild it. I’m confident it’ll run, since I had it running before disassembly. The clutch plates, however, appear to be fused together after a half-century of napping in a shed. I even tried the “kick it in gear while pulling the clutch” trick. The result? Nothing freed up, but I did get some excellent cardio.

Stay tuned — next chapter will likely feature me discovering what 60 years of British engineering looks like from the inside. Spoiler: probably oily.

Just got back from the weekly Saturday morning 9:30 coffee at McDonald’s, where the London branch of the CVMG convenes to drink caffeine, swap stories, and gently remind me that buying a 1961 BSA was a “life choice” I’ll be explaining for years. Everyone congratulated me on my milestone (translation: the engine is out and I’m still married) and then promptly volunteered me to create a flyer for the September Swap Meet. Apparently, I “look like someone who knows computers.” They asked, and for once I didn’t lie — though in hindsight, maybe I should have. I’m trading BSA knowledge with Mario for how to work his technology.

I missed all the early spring swap meets, but I’m catching the late ones with a shopping list that currently reads: Exhaust/Silencer, clutch bits, and possibly a therapist. There’s one on September 6th and another on the 28th, which should give me plenty of chances to buy rusty parts at premium prices and ask enough questions to risk a lifetime ban. Now the only challenge is convincing Holly to subcontract the flyer project before the club finds out my real design skills peak at “WordArt.” :o)